Monthly Maintenance Checklist

A Trained Operator can perform the following maintenance tasks. If any maintenance items fail, measures should be taken to remedy the problem and prevent damage to the energy storage system.

Cabinet ID: | |

Technician: | |

Date: |

|

|---|

FIRE AND ELECTRICAL HAZARD

Failure to follow these instructions may result in injury. |

✅ Environment

Task | Pass/Fail | Notes |

|---|---|---|

Check for pooling water and water damage (water stains, mold) | ☐ / ☐ |

|

Check for intrusion of pests (animal feces, chewed wires) | ☐ / ☐ |

|

Check if chemicals are stored nearby | ☐ / ☐ |

|

Remove obstructions in the vicinity of the battery | ☐ / ☐ |

|

✅ Cabinet

Task | Pass/Fail | Notes |

|---|---|---|

Clean exterior surfaces. Use a soft cloth and approved cleaner to remove dust, residue, and dirt. | ☐ / ☐ |

|

Inspect painted surfaces. Look for rust, paint chips, or mechanical damage. | ☐ / ☐ | |

Inspect gasket and seal integrity. Check door and panel gaskets for cracking, gaps, or hardening.

Rubber Waterproof Seal | ☐ / ☐ |

|

Confirm there is no water in the bottom groove of the door. | ☐ / ☐ | |

Battery pack fasteners and retention brackets are tight. | ☐ / ☐ | |

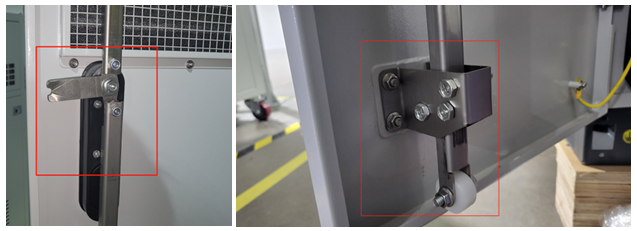

Confirm door rods and other components are assembled tightly and fit well.

| ☐ / ☐ | |

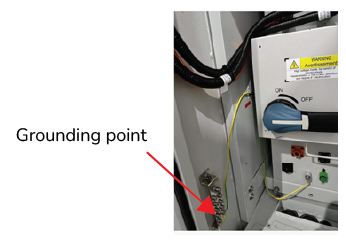

Check the grounding point, make sure the screws of the grounding point are not loosened, rusted or sheared off. The resistance between grounding points should be less than 1 Ω.  | ☐ / ☐ | |

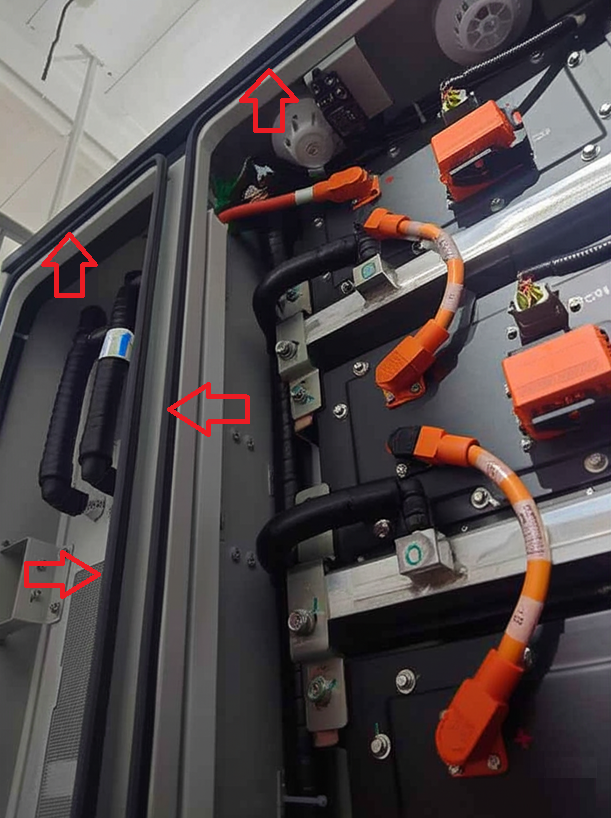

Confirm all external connections and protective covers in the cabinet are closed.  External Connection Points and Protective Covers Should be as Shown | ☐ / ☐ | |

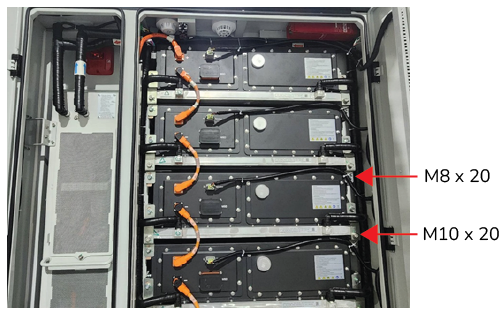

Using a torque wrench, check that the fasteners on the liquid cooler, high voltage box, battery box, and battery rack brackets are firmly installed and at the correct torque.

Battery Pack Retention Brackets | ☐ / ☐ | |

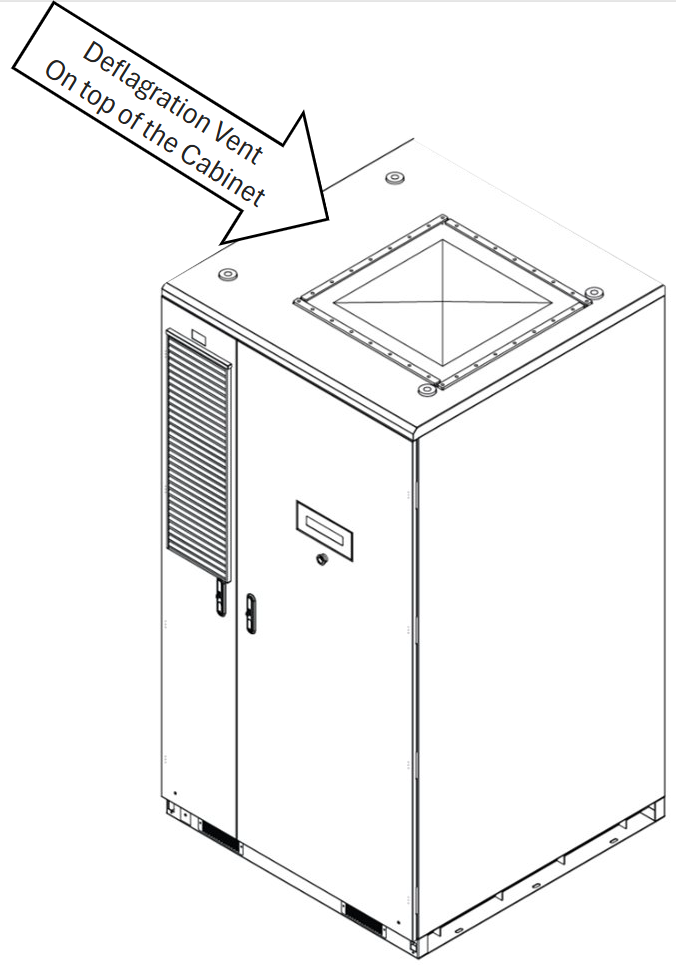

Ventilation pathway check. Confirm passive deflagration vents and airflow inlets/outlets are unobstructed.  | ☐ / ☐ |

|

✅ LYNK II Monitoring

Task | Pass/Fail | Notes |

|---|---|---|

Log into LYNK Access or LYNK Cloud to verify SOC, temperature, and fault status. | ☐ / ☐ |

|

Review the status and history of alarms. Pay attention to alarms that may signal failing parts on the battery, such as component-related alarms and over and under temperature warnings. | ☐ / ☐ |

|

Review full charge cycles. Confirm the battery is getting charged to 100% SOC at least once a week to promote balanced battery cells. | ☐ / ☐ | |

Record operating parameters and review system logs.

| ☐ / ☐ |

|

✅ Dehumidifier System

Task | Pass/Fail | Notes |

|---|---|---|

Ensure the dehumidifier unit is securely mounted and unobstructed. | ☐ / ☐ |

|

Inspect the exterior of the dehumidifier for damage or corrosion. | ☐ / ☐ | |

Check for signs of moisture or condensation inside the cabinet. Check for water ingress, corrosion, or physical damage. | ☐ / ☐ |

|

Inspect wiring and connectors for loose or damaged components. | ☐ / ☐ |