Annual Maintenance Checklist

A Trained Operator can perform the following maintenance tasks. If any maintenance items fail, measures should be taken to remedy the problem and prevent damage to the energy storage system.

The following maintenance tasks should be performed once a year, in addition to the tasks listed in the Monthly Maintenance Checklist and the Quarterly Maintenance Checklist.

Cabinet ID: |

|

Technician: |

|

Date: |

|

✅ System Annual Test (SAT)

Task | Pass/Fail | Notes |

|---|---|---|

The SAT is performed by a Qualified Service Operator.

| ☐ / ☐ | This test is an exception to all the other annual maintenance tasks that can be performed by a Trained Operator. |

✅ Inverter / Battery Functional Test

Task | Pass/Fail | Notes |

|---|---|---|

Using the inverter interface, verify charge/discharge and closed-loop control between battery and inverter. | ☐ / ☐ |

✅ Grounding Resistance Check

Task | Pass/Fail | Notes |

|---|---|---|

Measure cabinet ground resistance (<1Ω). Clean contact points, if required. | ☐ / ☐ |

✅ Cabinet

Task | Pass/Fail | Notes |

|---|---|---|

Inspect enclosure seams and structural joints.

| ☐ / ☐ |

|

Confirm the airways of the deflagration vent are clear. | ☐ / ☐ | |

Inspect cooling fans inside the cabinet | ☐ / ☐ |

|

Replace if fan is failing or vibrating, or an alarm is detected. | ☐ / ☐ |

|

✅ LYNK II

Task | Pass/Fail | Notes |

|---|---|---|

Check current firmware of the LYNK II. Apply updates per Discover’s documentation and procedures. | ☐ / ☐ | |

Update the BCU firmware only as directed by Discover Energy. | ☐ / ☐ |

|

Use LYNK ACCESS to confirm fault-free operation.

| ☐ / ☐ |

|

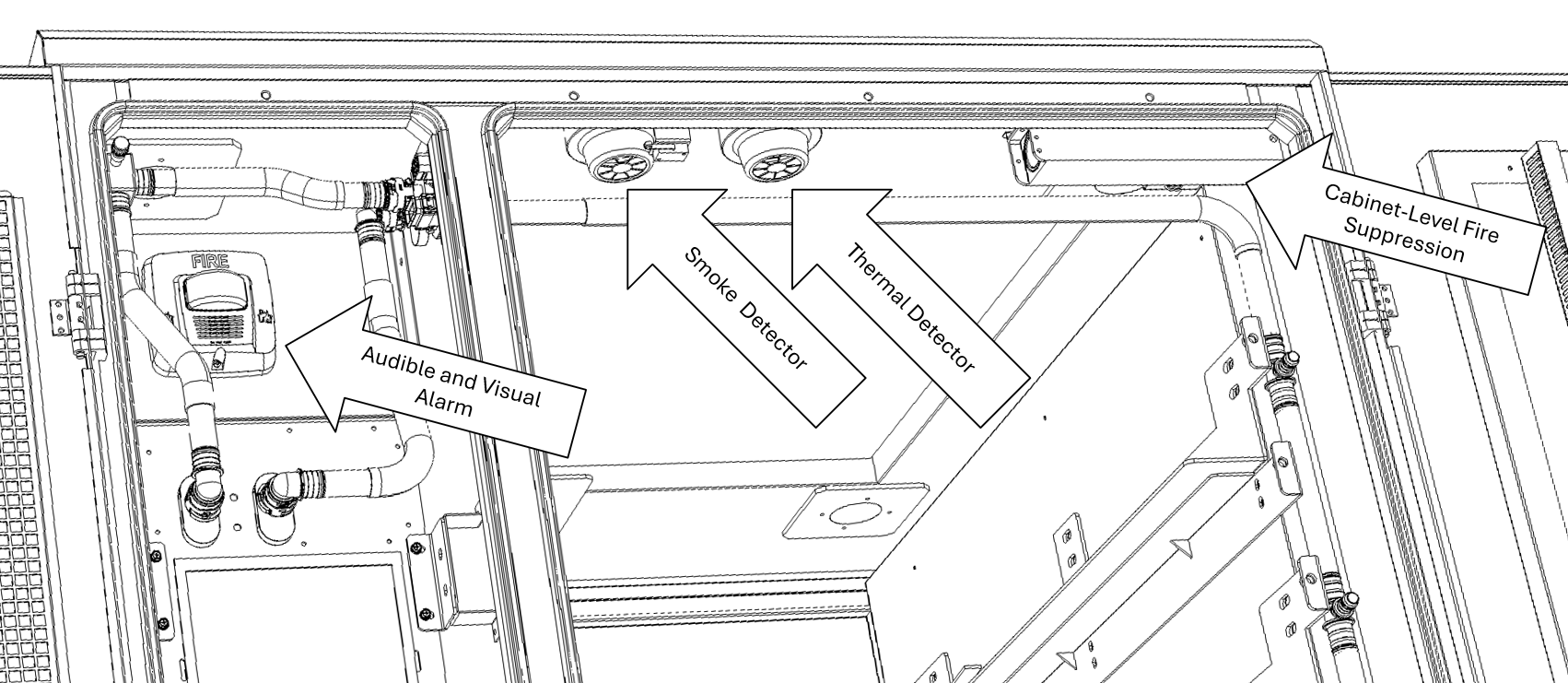

✅ Fire Suppression System

Task | Pass/Fail | Notes |

|---|---|---|

Visually inspect the aerosol canister (FS0050) for corrosion, physical damage, or displacement. | ☐ / ☐ |

|

Confirm the canister is securely mounted. Check the tightening marks on mounting screws to ensure canisters have not moved or loosened. | ☐ / ☐ | |

Inspect the wiring and sensor positioning. | ☐ / ☐ |

✅ Battery Pack

Task | Pass/Fail | Notes |

|---|---|---|

Visually inspect for physical damage, swelling, or corrosion. | ☐ / ☐ |

|

Check for discoloration or other signs of overheating on the battery cables, wires, ring terminals (wire ends), and fuses. | ☐ / ☐ |

|

Verify all battery and busbar terminals are torqued to spec.

| ☐ / ☐ |

|

✅ Thermal Management System

Task | Pass/Fail | Notes |

|---|---|---|

| ☐ / ☐ |   |

Confirm inlet/outlet temperatures.

| ☐ / ☐ |

|

✅ Dehumidifier System

The dehumidifier is part of the auxiliary systems and powered via the 24 V UPS.

Task | Pass/Fail | Notes |

|---|---|---|

Clean or replace filters | ☐ / ☐ | |

Confirm power supply voltage (24 Vdc) is within range. | ☐ / ☐ | |

Confirm operation and airflow. Check for errors on the screen. | ☐ / ☐ | |

Confirm CAN communication status with LYNK ACCESS. | ☐ / ☐ |

|

Check for fault codes or malfunction indicators in LYNK ACCESS. | ☐ / ☐ | |

Confirm the firmware and parameter settings match the expected configuration. | ☐ / ☐ |

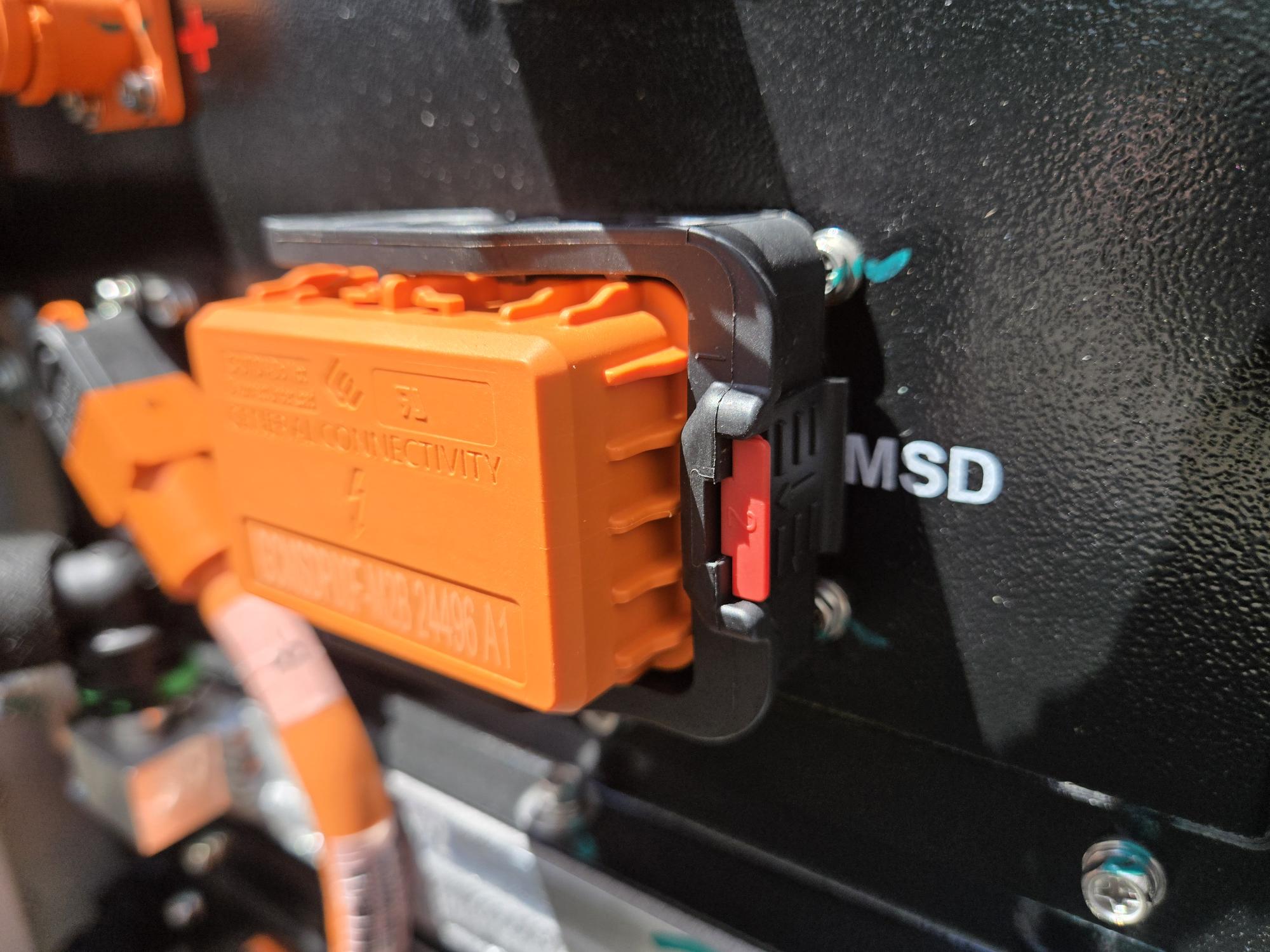

✅ Manual Service Disconnect (MSD)

Task | Pass/Fail | Notes |

|---|---|---|

| ☐ / ☐ | |

| ☐ / ☐ |

|

| ☐ / ☐ |

|